THE BDS CORE DRILL SERIES

HSS Standard Core Drills

The BDS base range. This is where the professional user has the greatest depth of product range at his disposal. • Core drills with three different cutting depths: 30 mm, 55 mm und 110 mm • Core drill diameters from 12 mm to 130 mm • With Weldon arbor 19 mm or 32 mm The BDS standard range of core drills has long service life and high heat resistance by the use of high-performance steel. Drilling without excessive use of force characterises the tools of this allround range. These core drills on request are also available in different shanks like Universal Shank, Nitto Shank or Quick-In Shank.

HSS VarioPLUS Core Drills

High-strength fully ground core drills that are machined under the effect of plasma with a hard coating in the range of 2.5 μ. As a result, these tools have considerably longer life and more uniform removal of chips, particularly with long drills. An important aspect for occupational safety. These core drills on request are also available in different shanks like Universal Shank, Nitto Shank or Quick-In Shank.

HSS Cobalt 8% Core Drills

The objective of this most recent product development at BDS was to produce a range of core drills optimised for power with greater heat resistance and better protection against wear. The desired results were achieved by an enhanced proportion of cobalt in special steel. These core drills are suitable for higher levels of stress in fine-grained steel and stainless material in conjunction with speed controlled BDS magnetic core drilling machines. The core drills can be ground again subsequently so that they retain their favorable product characteristics. HSS-Co 8 core drills can be identified by the black ring, the signature mark on the shaft! These core drills on request are also available in different shanks like Universal Shank, Nitto Shank or Quick-In Shank.

CarbideRAIL Core Drills

Carbide-tipped annular cutters for rail drilling, specially developed to drill hard and corroded material. Hard-tipped annular cutters have become a successful range of tools worldwide. BDS provides for the rising demand by expanding its range with specially developed carbide cutter for rail drilling. BDS develops the special TCT annular cutters for rail track drilling. In the rail processing sector, BDS offers two new and completely redeveloped machines: The RailMAB 925 with 1,600 Watt motor and 2-stage oil bath gearbox and the RailMAB 960 core drilling machine with petrol engine.

CarbidePLUS Core Drills

Core drills of the Carbide PLUS range are coated with hard, wear-resistant material under the effect of plasma in another work step. Tools of this range are used preferably for machining stainless steel and in combination with the drill emulsion, BDS 5000. These core drills on request are also available in Universal Shank.

Carbide Standard Core Drills

Hard-tipped core drills have become a successful range of tools worldwide. BDS is contributing to this growing demand by expanding the range with cutting depths of 30 mm, 55 mm and 110 mm length and almost continuous gradation from ø 14 mm to ø 150 mm.These core drills on request are also available in Universal Shank.

ORIGINAL BDS CORE DRILLING PRODUCTION

Product quality is not a coincidence

BDS produces core drills at their facility in Mönchengladbach, with all the benefits for users worldwide:

- High manufacturing precision and competence

- Use of steels from well-known manufacturers

- Short-term availability and fast delivery

BDS magnetic core drilling machines and core drilling tools must be considered as a functional unit. Thus, the development of in-house core drill production was expedited right from the beginning in parallel to the production of the machines. This is why the core drills of BDS today are on top worldwide.

The correct tool for any application

The particularly comprehensive range of BDS core drilling tools is justified by the diversity of the applications and materials handled. Starting with the HSS core drills of the standard range, the most comprehensive range of tools with short, long and extra-long core drills, there are those with hard coatings, the large group of carbide drills and, as the most recent development, HSS-Co 8 core drills with 8% of cobalt content. Significant features of the BDS core drill tools are machining of full cuts and the high precision in geometry and concentricity associated with it, as well as optimised removal of shavings, high level of stability using qualitatively highclass types of steel. The VarioPLUS core drills with hard coatings ensure a high degree of wear resistance and long service life as a result of the good surface quality and hardness.

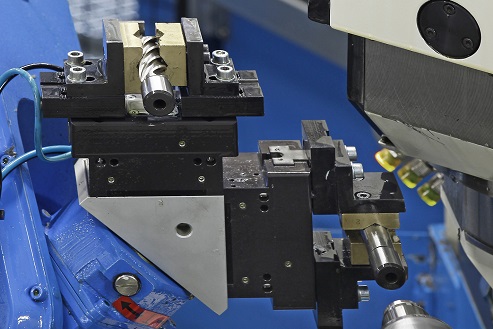

Know-how and technology – the recipe for quality

BDS produces high-performance tools on the most modern high-power grinding stations, which are partially based on in-house construction and program ideas and concepts and have been developed and built particularly for BDS. The large production capacity set up at the corporate premises forms the basis of the high availability of the BDS core drill tools that are exported worldwide from Germany at present. The experience of our employees having put in many years of service contributes towards ensuring a significant part of the success.